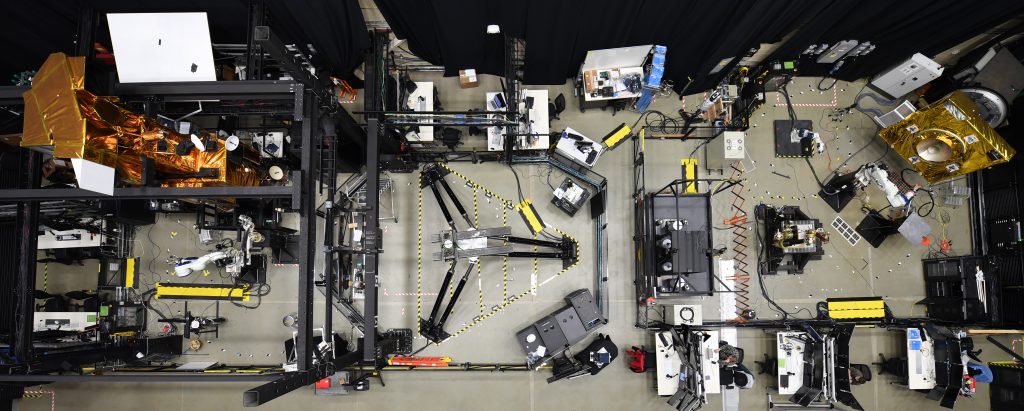

The Robotic Operations Center acts as an incubator for satellite servicing technologies that will allow NASA to repair, refuel, and upgrade spacecraft. In this lab, engineers test robotic capabilities in space-like conditions before they are put to action in orbit. Photo credit: NASA

The Robotic Operations Center at NASA’s Goddard Space Flight Center is the testing ground for new technologies in development by the Satellite Servicing Projects Division (SSPD), a Goddard team dedicated to ending the era of “one-and-done” spacecraft through robotic servicing missions. Now, NASA’s technologists and technology transfer professionals are seeking to transfer these technologies to interested U.S. companies, ultimately helping to jumpstart a competitive market.

SSPD will host its fourth Technology Transfer Industry Day on Sept. 18 at Goddard’s main campus in Greenbelt, Maryland. The meeting will cover a broad span of topic categories, including on-orbit servicing, assembly, and manufacturing (OSAM). Co-hosts include NASA’s Langley Research Center, which will present on assembly, and NASA’s Marshall Space Flight Center, which will present on manufacturing.

In-orbit satellites can gain a second life by receiving new fuel and repairs from robotic spacecraft, which are currently in development at Goddard. The Restore-L mission, scheduled to launch in 2022, will send a robotic spacecraft to refuel a satellite not designed to be serviced — Earth science satellite Landsat-7 — for the first time ever. The mission will utilize a number of new technologies to autonomously navigate to, rendezvous with, grasp, refuel and release the satellite. In-space assembly can enable the construction of large-scale telescopes and other complex structures without volume limits imposed by rockets. In-space manufacturing contributes to the ability to adapt to unforeseen circumstances in space. Together, servicing, assembly, and manufacturing help make spaceflight more flexible, resilient, and sustainable.

Domestic companies with interest in technologies to service spacecraft; developing spacecraft that are more easily serviceable; assembly; manufacturing; and related capabilities are encouraged to attend this event. Throughout the day, attendees will have access to an updated satellite servicing technology catalog, information about the latest developments from NASA subject matter experts, and a tour of Goddard’s Robotic Operations Center.

In the coming decades, robotic servicing is expected to bring about the dawn of a new era of extended spacecraft utility, saving billions of dollars in satellite manufacturing costs. To get there, NASA and industry will need to work together and facilitate the transfer of technology to make this vision of the future a reality.

NASA welcomes companies interested in learning more about OSAM, sample collection and return, human exploration, or orbital debris mitigation/remediation. To learn more, visit the FedBizOpps posting for additional information and registration details.