| Skip to content | |||||

|

|

||||

|

|

|

||||||||||||||||

|

|

Finding multiple avenues for single innovations

The IPP Office strives to find as many avenues of technology transfer as possible for each Goddard innovation. In FY07, several technologies were the subject of multiple success stories due to broad applicability of the innovation; support and enthusiasm from innovators who took active roles in the technology transfer and partnering processes; and diligent, aggressive work from IPP Office staff who cultivated multiple partner relationships. FY07 brought with it several technology transfer agreements related to Goddard’s Link and Switch implementation of the international SpaceWire protocol, which is a set of serial links that describe a space computer network used to transfer information defined in packets. Developed by innovator Glenn Rakow, Goddard’s Link and Switch provides several additional features that improve the reliability and usability of the SpaceWire standard for space-flight applications. Researchers and IPP Office staff knew that it would generate much interest in the aerospace community if they could make information about the innovation widely available. Their efforts began in 2006 when they developed a strategy to make the technology available free of charge via Software Usage Agreements (SUAs). As a result, nearly every major U.S. aerospace company in the U.S. has evaluated Goddard’s technology. And three major corporations—Aeroflex, Harris, and BAE Systems—all signed reimbursable Space Act Agreements (SAAs) in FY06 or 07, soliciting Goddard’s expertise in integrating the technology into their avionics electronic products. Their products will contain native SpaceWire functionality, giving them a competitive edge, while NASA missions will benefit from the increased availability of SpaceWire-based electronics. Finally, the aerospace industry as a whole will benefit from the increased acceptance of the SpaceWire standard, which provides for compatibility and efficient reuse of avionics components—saving all aerospace organizations valuable time and resources.

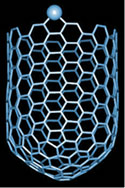

Although carbon nanotubes were discovered 15 years ago, their use has been limited due to the complex, dangerous, and expensive methods required for their production. However, Goddard scientists developed a simpler, safer, and much less expensive manufacturing process for single-walled carbon nanotubes (SWCNTs). The key innovation in this process was its ability to produce bundles of SWCNTs without using a metal catalyst, dramatically reducing pre- and post-production costs while generating higher yields and greater purity. These significant benefits caught the attention of several small and growing nanotechnology companies in FY07. “By bringing costs down while pushing quality up, we can help the industry increase adoption of this valuable technology,” said Ramon Perales, president of Nanotailor, Inc.—one of three com-panies that licensed Goddard’s SWCNT manufacturing process this year. Like Nanotailor, the other two companies—E-City Nanotechnologies and American GFM—licensed the technology to take advantage of the competitive differentiation that Goddard’s method offers. These three licenses are added to the license signed in FY06 with Idaho Space Materials, bringing the SWCNT manufacturing process license count to four. And as more companies begin developing high-quality, affordable SWCNTs, industries ranging from medical to microelectronics will benefit from increased availability of this important nanotechnology.

|

||||||||||||||||

|

|||||||||||||||||